Protective foil

Laminated protective foils should be removed immediately after installation but not later than 4 weeks after delivery.

Installation of FischerTHERM roof elements

Place packages on the roof purlins using a crane.

Distribute the pallets so that the substructure is evenly loaded, ideally near trusses or girders.

On sloped roofs, packages must be protected from slipping off the substructure.

When packages have been opened, protect the roof elements from storm. When placing the packages, take account of the laying direction of FischerTHERM® DL roof panels.

Laying single panels using a crane has proven to be practicable and economical. Make sure that the single panels are not subject to major deflection during crane movements.

If a building crane is not used, carry the roof panels from the package to the place of installation. Do not push or drag them over completed roof surfaces.

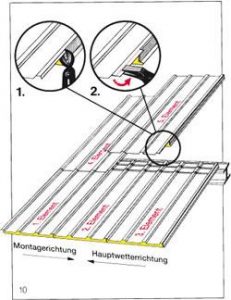

If possible, FischerTHERM® roof components should be laid against the main wind direction.

Prior to commencing the installation work, create a working platform by laying at least one panel beside the package to be stored.

Temporarily fasten this panel, e.g. using screw clamps. From this platform measure the first panel to be placed and bring it into the installation position.

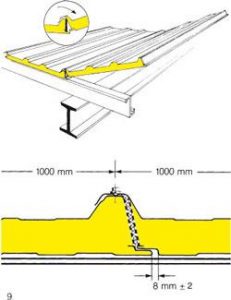

Then place the next element with the foam-free longitudinal joint overlap onto the end rib of the previously installed element so that the longitudinal joint is closed. The joint should be approx. 8mm.

For cross joint designs, first place a few panels in the eaves area and then in the ridge area so that they overlap.

In the case of cross joint overlaps, two sealing tapes must be applied to the panels to be overlapped.

Prior to that, the vertical sheet web must be cut using plate shears right at the rigid foam core. Then open the sheet web horizontally using locking pliers.

To fasten the roof components to the substructure start with the longitudinal joint. At the end of each workday, the panels should be completely fastened. In the case of cross joint overlaps, place two sealing strips on the component to be overlapped. Between the two foamed surfaces in the area of the cross joint, a permanently elastic, compressed sealing strip should be inserted so as to ensure thermal insulation and air tightness.

The roof components are fastened to the steel purlins through the upper and the lower chord using approved thread forming or thread cutting stainless steel screws. Wooden purlins usually require predrilling, however there are special tapping screws for wood which make predrilling unnecessary. Longitudinal joints are fastened using thread forming or thread cutting stainless steel screws spaced at max. 500 mm. When using screws with an undercut, the outer sheet of the overlap need not be predrilled so as to ensure that the two sheets are pulled together. Chips from drilling must be immediately removed so as to avoid damage to the roof panels which might affect corrosion protection.

Roof apertures

Basically, domelights or smoke and heat outlets can be provided in any type of metallic roofing but their installation is rather laborious, and the units are often liable to damage. In any case, they are quite expensive. Therefore, the usual method is to provide a row of skylights close to and parallel to the eaves or the ridge for lighting as well as for smoke and heat extraction. Pipe ducts can be conveniently and safely installed e.g. using EJOT Flash.

Cutting FischerTHERM® sandwich panels requires the utmost care so as to prevent cover sheets coming apart due to incorrect handling or blunt or unsuitable saw blades. Wall panels should be positioned with the outer sheet at the bottom. It is recommended that the area where cutting will take place is supported using wooden boards and screw clamps. The panels should be cut in places that will be covered by other building elements or folded profiles. Cuts in panels, which will be visible after installation or which will be exposed to weathering, should be retouched using suitable lacquer.